Naturally, there was a spreadsheet involved.

My goal was to max out reliability and moderate cost.

I looked at a new FA20 short block, but the passenger side head was compromised. Then I thought FA20 long block, but that was basically good money after bad. I never complained about the torque dip as I rarely spent any time in it, but this just seemed like a MEH idea. Whole used engine, nope, because it would be just another ticking time bomb with me driving it. I also thought about doing an FA22 (FA24 short block/FA20 heads), but machine shop time…. too much stress. So also no.

Then an FA24 with 15K on it showed up. Hello and nice to meet you. Thank you to the friend who linked me to it!

The total for the swap is not small money, but it is also not big money, considering what engine swaps can cost you. The main thing is that you can run the FA24 on the FA20 ECU and wiring harness. This is a very non-trivial savings!

Engine – $6K

Assorted fasteners and gaskets (dealer/Amazon) – $150

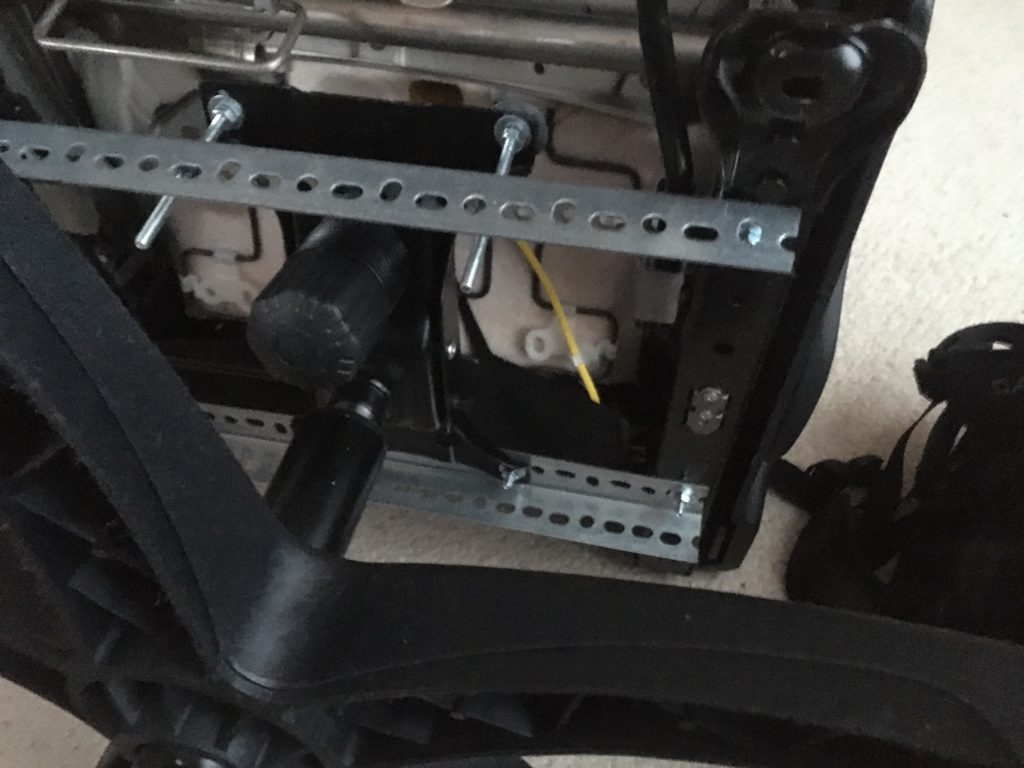

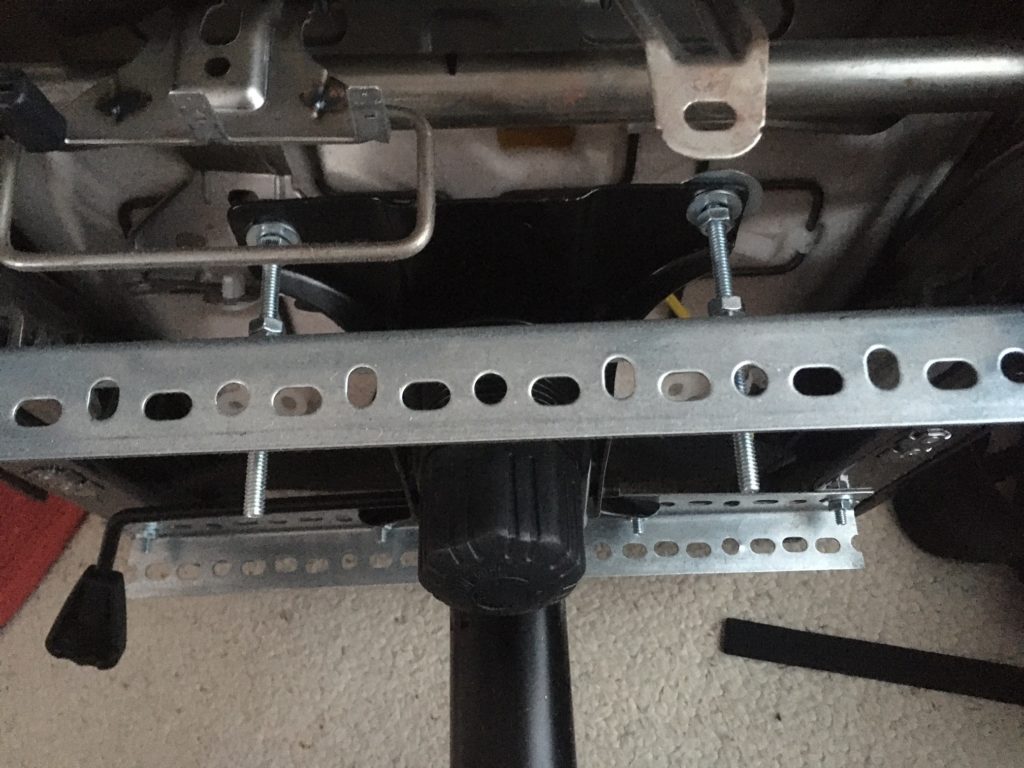

Verus ECU bracket – $70

Hachi harness bits – $200

Tomei Joint Pipe – $235

I’ve also gone ahead and pre-ordered the Formula Delta oil pan as I do track the little beastie. If I end up paying for tuning, figure another $400 for that. I also upgraded to the Verus Forged clutch fork. If one person was the rock star here, it was the shipping clerk at Verus. They were on it – both orders shipped silly fast.

I usually make my own connectors, but I’m glad I ordered the Hachi bits. Very nicely made, labeled professionally, and I got to support a tiny aftermarket dude who uses the Farmington Hills font. If you are local to SE Michigan, you know what I am talking about.

The decision to upgrade the exhaust joint pipe came after discussion with a colleague who has experience in that sort of thing (Detroit peeps rock. Seriously). Rather than fool with the manifold (I did get a Tomei UEL catless with the engine) and risk fitment issues with the Formula Delta pan, I opted to go for a stock manifold. The factory exhaust manifold has a cat which is considerably larger than the FA20 unit, so good there, but the FA20 joint pipe (right after the cat) is … not big … and is a known bottleneck in the exhaust. The Tomei unit is straight through 60mm, over the 54mm weirdly internally shaped stock one. That will mitigate any downstream issues. It drones pretty badly at idle with the stock one, hopefully that goes away because it is BAD.

I kept the FA20 AC compressor (never unhooked it, just bolted it back to the FA24 which avoided refrigerant loss) and the FA20 alternator and bracket. The AC compressor rear mounting buss was there and threaded, just unused. The alternator bracket is not going anywhere with only three of four bolts in it.

The swap was the lowest drama swap I’ve ever done aside from a dead-factory one. That includes several VW swaps Mk1-Mk4, where there is no Body Control Module to deal with. Honestly, it was as easy as a stock Mk1 swap. There was literally nothing to do except forget to plug in the High Pressure Fuel Pump and wonder why it wasn’t running well. Once that was done, it fired up and went into idle calibration perfectly. If I help with another car, I think I could do this in a weekend, possibly even in a single day. If I subtract the teardown of the FA20 and my missed points (the clutch fork needs to be all the way on the ball mount, HPFP connector, missing hardware, yadda yadda…), it could definitely be done in a longish day.

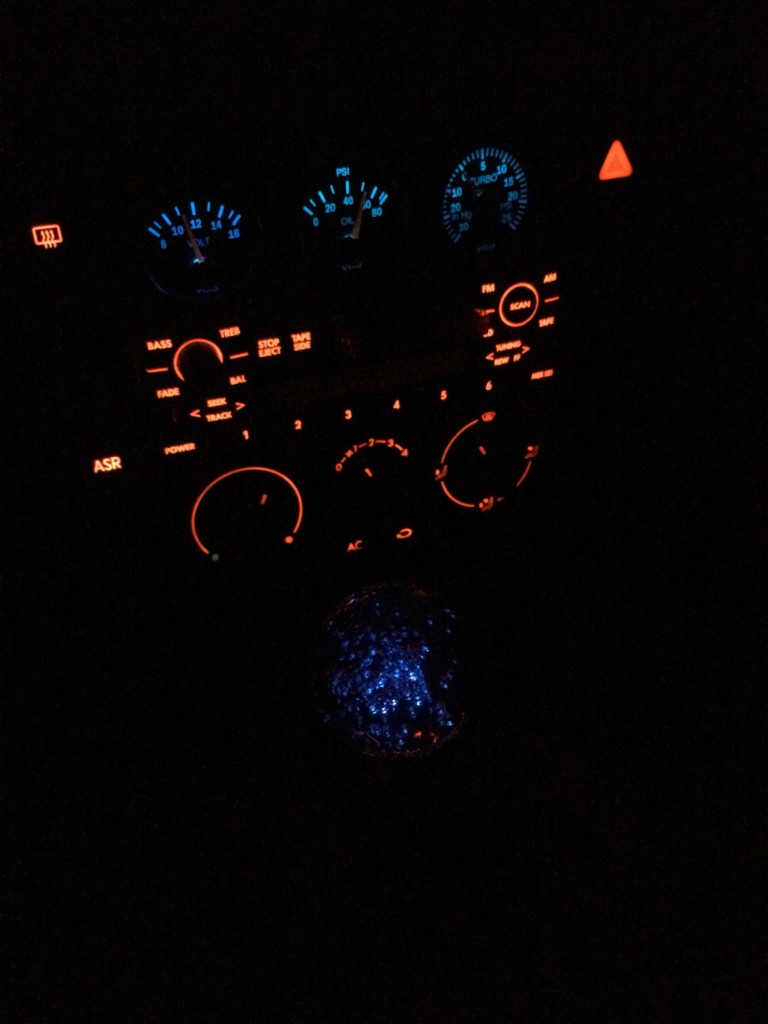

I’ll be tuning with an OpenFlashPerformance tool with support from a friend who actually knows what they are doing to get it on the road safely.

Yes, you can buy horsepower. I guess I have to make a new sticker. No more torque dip.